wye delta starter troubleshooting

Rated load amps RLA. The counter emf should have been reduced.

How To Troubleshoot 3 Phase Induction Motor Step By Step Guide Engineer S Portal

WYE DELTA MOTOR STARTER DIAGRAM PDF.

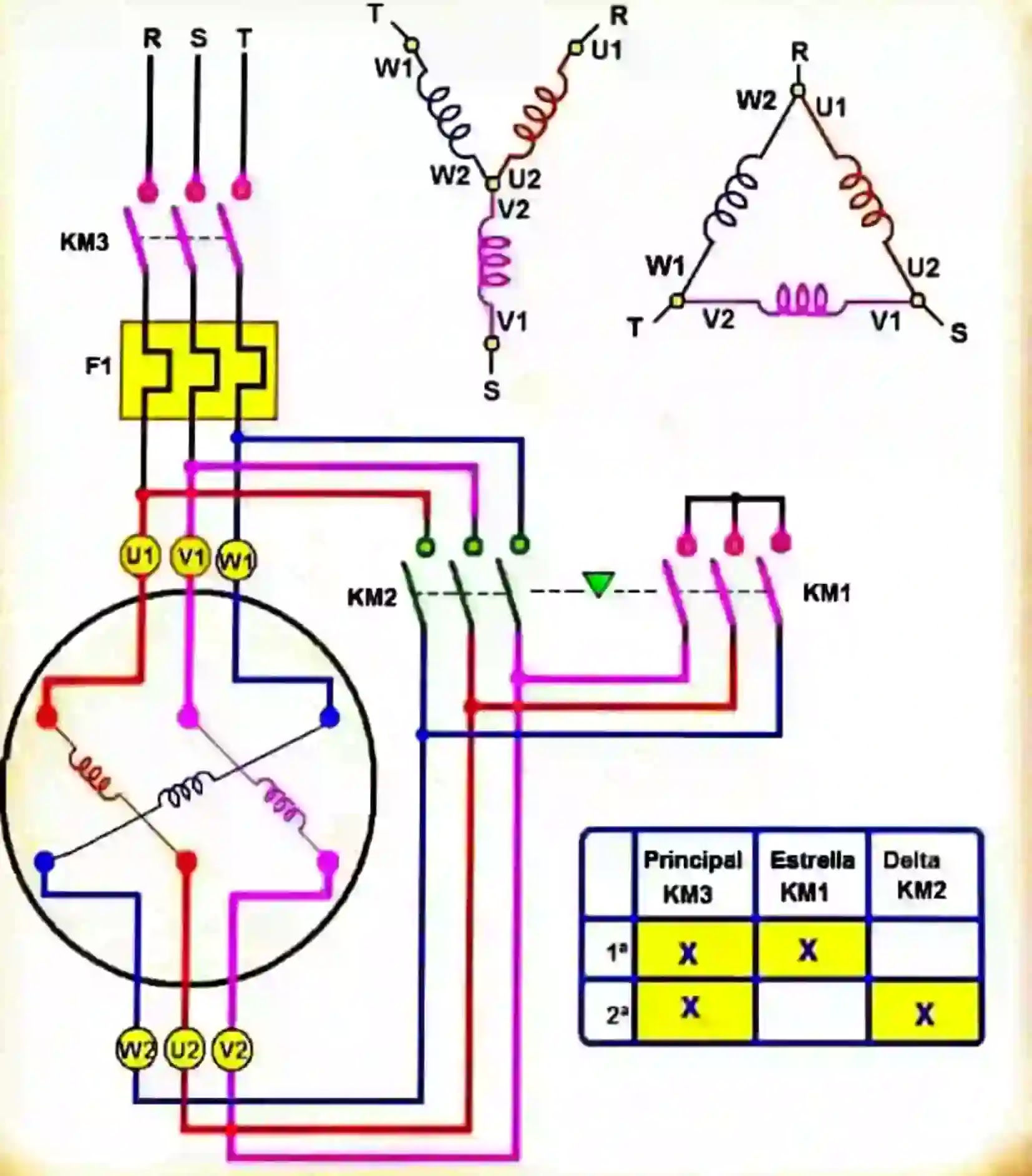

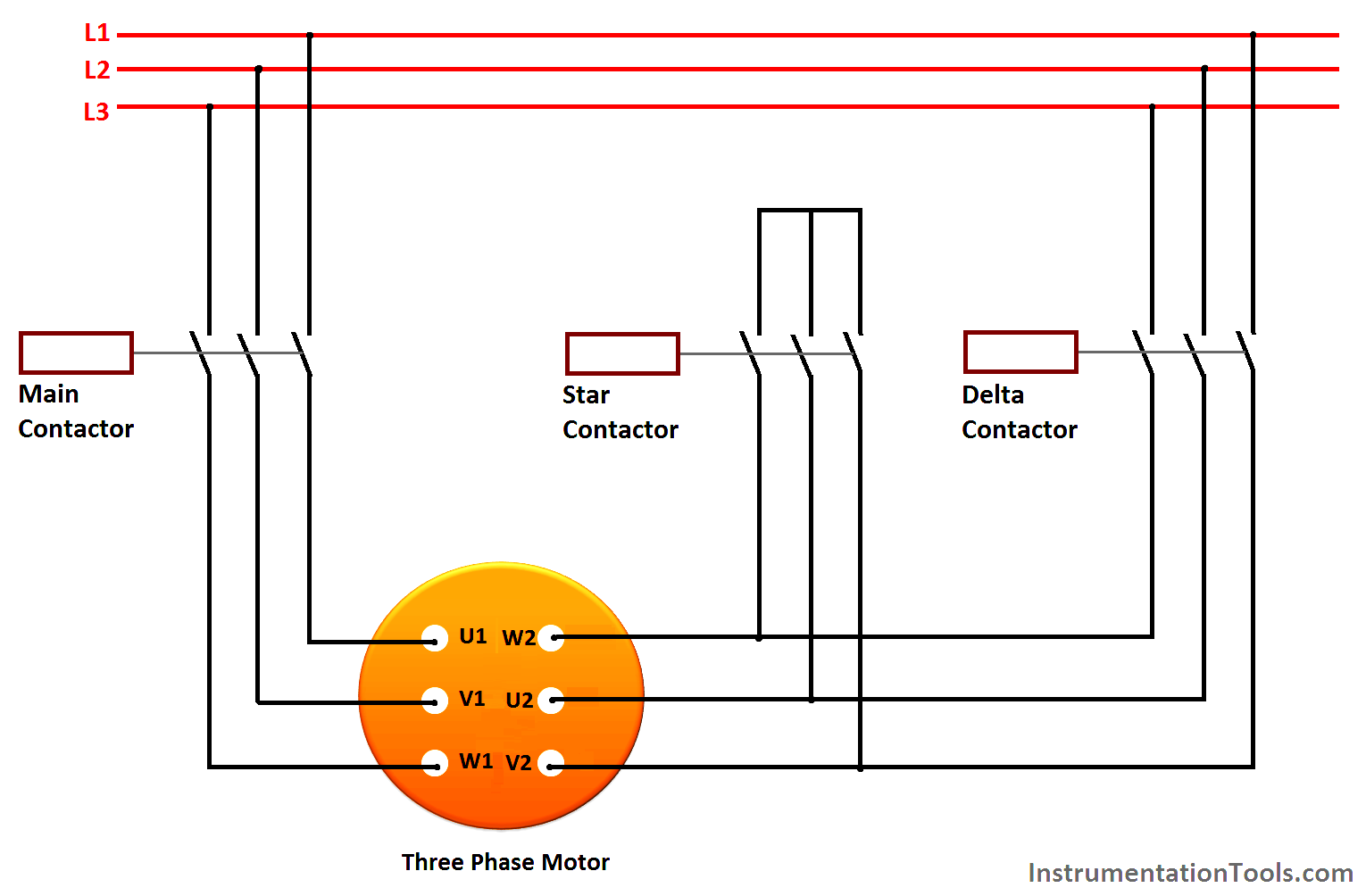

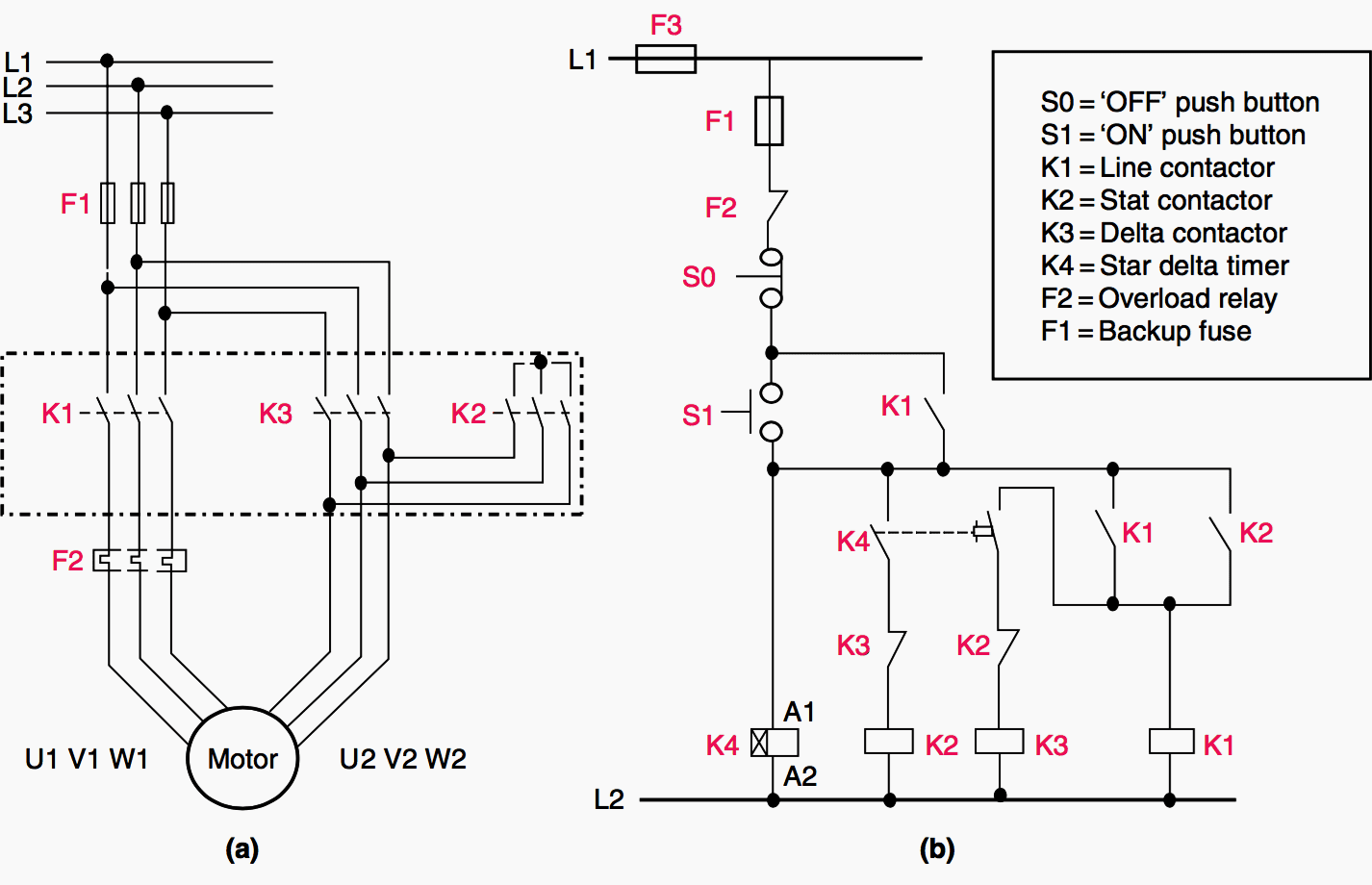

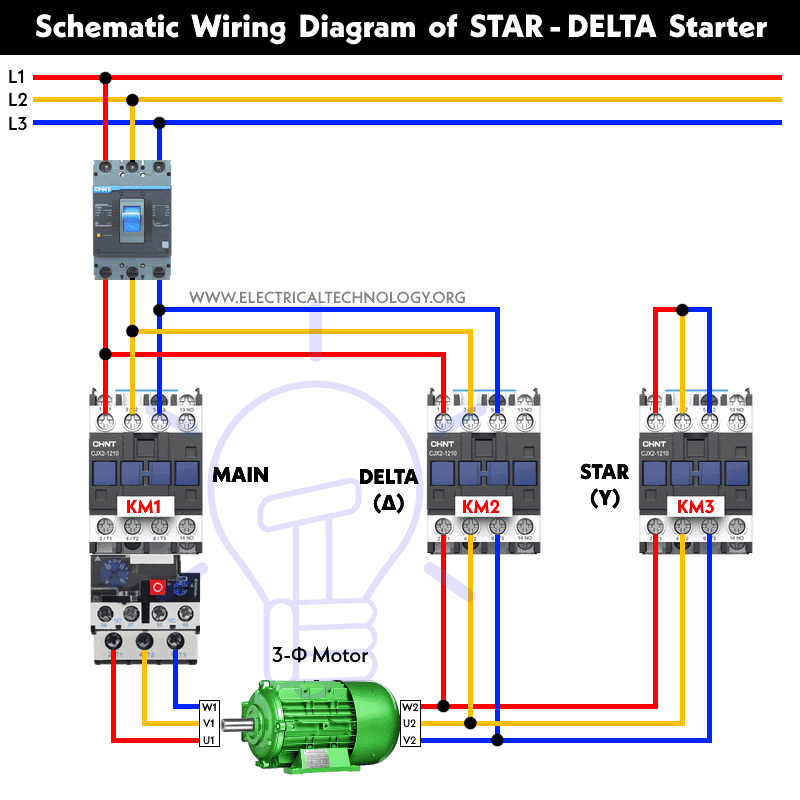

. The primary and secondary of a three-phase. Figure 3 is the schematic for a DeltaWye configuration. The typical circuit includes three separate contactors an overload relay a timer and an interlock.

Before troubleshooting the 3 phase induction motor we must have to know about the 3 phase induction motor star delta starter and its connection diagram. Use the clamp you have. This is a very well known problem with Open Transition Wye-Delta starting.

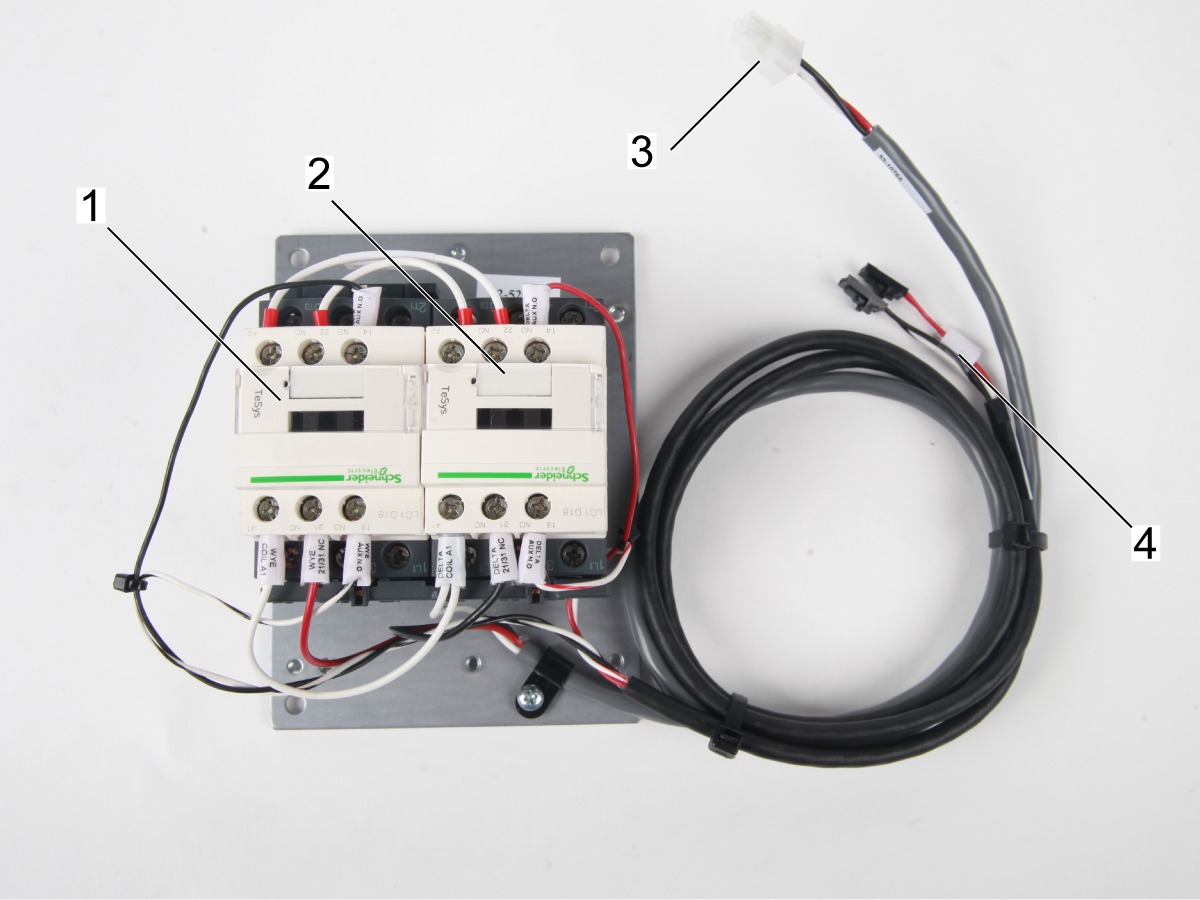

With 480 V three-phase power applied to the three power terminals of a wye-. The WYEDELTA patch is enabled and the WYEDELTA contactors do not have a feeback cable. Even on an unloaded start a 300Hp will need more than 2 seconds to get away.

Here we are giving you only overview on 3 phases induction motor. Assume U V and W. The soft starter is a solid state device so mechanical issues and maintenance are.

In order to note the symmetry of the transformation equations the Wye Y and Delta. See the NGC-WYE-DELTA with Feedback Troubleshooting section below. The primary is wound as Delta and the secondary is wound as Wye.

Star-delta starter Wye-Delta Starters Circuit working Induction motors are robust and reliable and are used in all industries across the globe. DeltaDelta is used in many industrial installations while DeltaWye is the most common configuration. Solid-State Starters The most widely used configuration of the electromechanical wye-delta starter is referred to as open transition.

This course describes the similarities and differences between a wye-delta motor starter application and a full-voltage motor starter application. You switch from wye to delta after 25 to 4 seconds but the switch is instantaneous. Troubleshooting and commission a simple task.

Once the motor runs at full speed in wye disconnect the power to the wye contactor coil let the speed fall to half and then connect power to the coil of the delta contactor. The WYEDELTA feeback cables are not connected or not connected correctly. This video covers the basics of a wye-delta motor starterFor other videos on reduced voltage starting methodsPart-winding starter.

Centrifugal compressor motors operate at a RLA significantly below their maximum full load amps. In this example there are two Y-networks comprising the first Y-network 24 Ω 30Ω and 30Ω and the second Y-network 10Ω 50Ω and 30 Ω. Actual amperage that the motor draws for a specific application.

Alarm 9973 or 49973 INVALID POWER CONTROL STATE DETECTED when the machine accelerates to maximum RPM. Delta to wye conversion of sources. Delta to Wye Conversion.

There is a loose. A Wye-Delta starter also known as Start Delta is one of the most commonly used methods for the starting of a three phase induction motor. 3 phase induction motor have 3 winding.

The StarDelta or WyeDelta starter is one of the lowest cost electromechanical reduced voltage starters that can be applied. It has to do with the phase shift that takes place when switching from Wye to Delta and how that interacts with any residual magnetism in the motor at that moment and the point in the sine wave at that moment etc. Inspect the vector drive and look for a shorted output.

WyeDelta is used in high voltage transmission and WyeWye is seldom used because of potential unbalance. When we need to transform a Delta Δ network to an equivalent Wye Y network the equations 65 to 67 are the useful expressions. Some wye-delta starters for large motors can cause peak currents in the power system to exceed the normal trip settings of branch circuit breakers.

It is equal to 0577 x RLA of the motor for a specific load. Check the Wye-Delta connections for arching or burn marks. Up to 24 cash back Wye-delta Transformation is already discussed in our lesson four blog but here we will give some examples and we will explain slowly step-by-step.

Analog Mixed-Signal Design. The current draw inside the delta connection of a wye-delta motor winding. Faulty Wye-Delta contactor assembly.

The problem is a low output voltage so yes just to raise the output voltage in a stable fashion to what it needs to be. There are numerous papers written about this available on the. Make sure the connections are tight.

Both types are diagrammed in accompanying illustrations. Closed transition starters do not permit this peak to occur. The StarDelta starter is manufactured from three contactors a timer and a thermal overload.

Starting in the wye configuration but wye-delta motor starting is a type of reduced-voltage motor starting. In this configuration of. In many if not most cases the stardelta starter does little to reduce problems infact it commonly exacerbates them.

1-bit to PCM conversion in Delta-Sigma converters. As its an unloaded start id set the Wye Delta to a second before the unloaders kick in. Various methods are followed to start induction motors out of which star-delta starters are the most commonly used ones to.

Alarm 116 SPINDLE ORIENTATION FAULT. Unlike all other types of starters the VFD can use frequency to limit the power and current delivered to the motor. Known as WyeDelta starters in the 60Hz world.

On the other hand the equations 612 614 are used for Wye Y to Delta Δ conversion. Thread starter Similar threads Forum Replies Date. Find Rab and i.

Configure a wye start delta run contactor set up with a potential relay or timer cutting off the wye contactor while using aux contact on wye contactor so Delta and Wye contactor can. Run in star and watch the current untill it levels out the change over to delta shouldnt really occur until the compressor is up to 75-80 speed minimum. So lets take it one by one.

Troubleshooting the most typical winding problems of three phase electric motors. They are used in an attempt to reduce the start current applied to the motor during start as a means of reducing the disturbances and interference on the electrical supply. It is the so-called open transition wye-delta starter thats the culprit.

Vector Drive - Troubleshooting Guide to troubleshoot the vector drive. A sample wiring diagram is included as Figure 9 on page 14. Would have been simple in my opine.

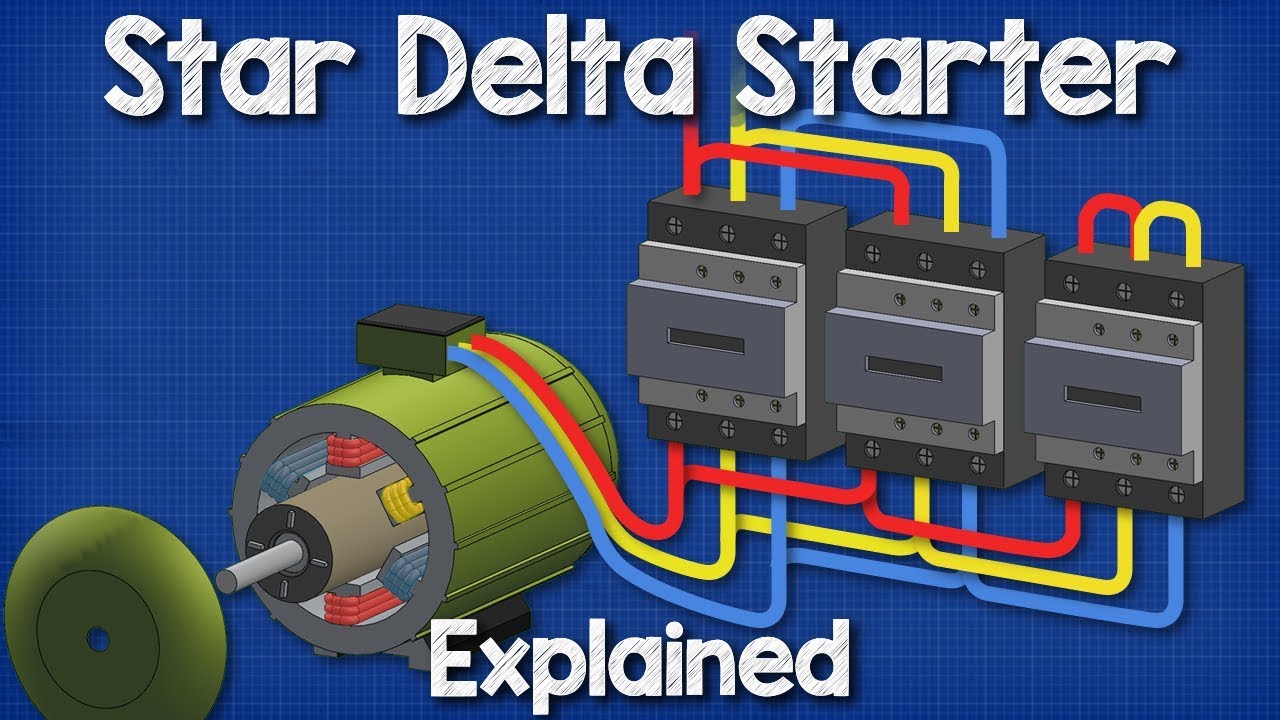

Star Delta Starter Explained Working Principle Youtube

3 Phase Induction Motor Star Delta Connection

45 Best Of Wye Delta Starter Wiring Diagram Circuit Diagram Electrical Wiring Diagram Electrical Circuit Diagram

Star Delta Starter Plc Program And Wiring Part 5

Star Delta Starter Theory And Working With Power And Control Circuit Electrical Technology All About Electrical Engineering

Troubleshooting Three Basic Hardwired Control Circuits Used In Circuit Diagram Electrical Circuit Diagram Electrical Diagram

Automatic Starters For Star Delta Motors

How To Troubleshoot 3 Phase Induction Motor Step By Step Guide Engineer S Portal

How To Troubleshoot 3 Phase Induction Motor Step By Step Guide Engineer S Portal

Plc Program For Star Delta Motor Starter Plc Motor Ladder Logics

How To Connect The Float Switch For Star Delta Starter Power Cable For Star Delta Connection Youtube

Erection Organ Basketball Overload Setting For Star Delta Starter Sponge Salesperson Leeds

Star Delta Starter Complete Wiring For 3 Phase Motor Star Delta Control Connection Explained Youtube

Automatic Star Delta Starter Control Circuit Diagram With Timer

Troubleshooting Three Basic Hardwired Control Circuits Used In Starting Electric Motor Eep

Star Delta Starter Motor Starting Method Power Control Wiring

Wye Delta Contactor Troubleshooting Guide Chc

Star Delta Motor Starter Troubleshooting

Motor Problem In Star Delta Starter In Air Compressor Electrical Engineering Stack Exchange